That moment of frustration is familiar to any engineer or technician: your laser rangefinder module consistently underperforms, failing to hit its specified distance targets. Before resigning yourself to costly replacements or complex repairs, a systematic diagnostic approach is key. Based on proven troubleshooting workflows, let’s explore the common culprits behind weak rangefinder performance and how to isolate them.

Check Environmental Conditions

Weather significantly impacts laser performance. Rain, snow, fog, and dust scatter the beam, reducing effective range. If atmospheric visibility is below the rangefinder’s specified threshold, degraded performance is likely.

Monitor local weather conditions and visibility reports. If visibility is low due to the mentioned conditions, the weather is likely the primary cause. The flowchart also notes that atmospheric turbulence (severe wind shear or thermal distortion) can create localized conditions worse than the general test environment, impacting performance.

Patience is often the solution here. Wait for improved weather conditions where visibility meets or exceeds the module's requirements. Reschedule testing or operation if possible.

Inspect the Optical Window

The optical window protects the rangefinder's delicate internal optics. However, issues with this window are a very frequent source of performance degradation.

Meticulously clean both sides of the optical window and the rangefinder's front lens using appropriate optics cleaning materials and techniques. Always try this first!

If cleaning fails or the window itself is faulty (wrong band, low transmittance, poor design), replace it with a window specifically matched to the laser wavelength and application requirements. Consult the manufacturer for specifications and installation guidance ("optical window selection and installation suggestions").

If window replacement isn't viable or sufficient, consider upgrading to a rangefinder module with inherently stronger output power ("replace with a more capable module").

Evaluate the Target

A poor target choice—too small, too dark, or angled—can weaken the return signal. The flowchart strongly recommends structures like buildings with large, flat, perpendicular surfaces. "If changing to a higher reflectivity or larger target restores capability to meet specs, judge the problem as unsuitable target selection."

Select a target that is large, has high reflectivity (light-colored, smooth surfaces are often better), and is positioned as close to perpendicular to the line-of-sight as possible. Avoid small, dark, or highly angled objects like thin poles or wires.

If your application requires measuring difficult targets, a more powerful rangefinder module might be necessary.

Monitor Operating Temperature

Electronic components and laser diodes have strict operating temperature ranges. Exceeding these limits impairs performance or causes shutdown.

When poor performance is observed, send a self-test command (if supported) or otherwise check the module's current operating temperature. The flowchart instructs: "When ranging capability decreases, send self-test command, check current rangefinder operating temperature." Allow the module to return to its specified ambient temperature range ("wait for temperature to return to normal") and retest. The only solution for this is to operate the rangefinder strictly within its specified temperature range.

Conclusion

Most rangefinder performance issues stem from environmental factors, optical obstructions, target selection, or temperature extremes. By systematically testing these areas, you can quickly identify and resolve the problem without unnecessary repairs or replacements. Always start with the simplest checks—cleaning the optics or changing the target—before considering hardware upgrades.

About the Author & Team, Eyoung Tech

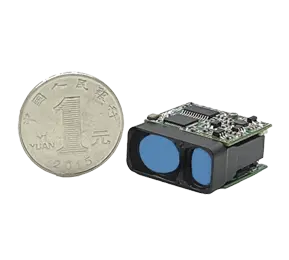

Hey, this is EyoungTech, a China-based professional team dedicated to advancing optoelectronic innovation.

With a steadfast focus on optoelectronic products represented by laser rangefinders and UAV payload pods, we deliver comprehensive, end-to-end solutions to leading international partners in the UAV & drone and defence sector. Backed by years of collective expertise, our stable, highly skilled workforce ensures rock-solid technical performance and unwavering support at every stage — from initial design through deployment and beyond. At Eyoung Technology, your mission success is our top priority.

The purpose of this article is to share with insight related to cutting-edge technlogy and product applications in defence, surveying of drone industry.

Eyoung Laser Ranging Devices and Gimbal Cameras

Related Eyoung and Photoelectric Products Article for Reference

Gimbal Cameras

Gimbal Cameras