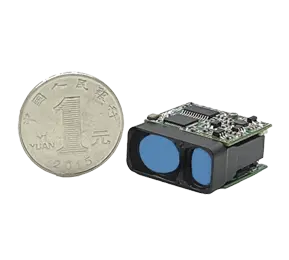

When your laser rangefinder module starts returning invalid measurements (for example, "65535" ), the issue typically falls into two categories: operational errors and hardware failures. Below, we break down the most common causes and how to diagnose and fix them.

Laser Rangefinder Module Operational Issues

Obstruction in optical path

Sometimes, when an operator or tester is conducting a test, he or she may accidentally block the transmitter or receiver of the laser rangefinder and fail to obtain the correct value. Therefore, you may check if the transmitter or receiver lens is blocked (dust, fingerprints, or physical barriers). And make sure the measurement environment is clear (avoid glass, corners, or reflective surfaces). Lastly, clean the lens with isopropyl alcohol and a microfiber cloth. Reposition the sensor to avoid obstructions.

Alignment and Beam Divergence Issues

Misalignment of the emitter and receiver optics is another frequent issue. If the laser beam is not aimed directly at the target or if the receiver is off-axis, the reflected signal may miss the sensor altogether.

Beam divergence — the natural spreading of the laser beam over distance — exacerbates this issue. At longer ranges, even a small angular misalignment can result in a significant deviation. As the beam spreads, its intensity per unit area diminishes, reducing the likelihood of a strong return signal and increasing the chances of invalid data.

You need to verify if the laser beam aligns with the target. Test at different angles—if readings stabilize after adjustment, misalignment is the issue. After that, recalibrate the optical axis (follow manufacturer guidelines). Use a collimator for precision alignment (for high-accuracy applications).

Laser Failure

Laser Diode Malfunction

The common symptoms are mainly no laser spot visible (test with IR card or CCD camera) and abnormal current fluctuations during operation. To diagnose the error, you can send a self-test command (if supported by firmware) or measure the drive current—if unstable or zero, the laser diode may be faulty. If it is confirmed that the laser is abnormal, do not repair it yourself at this time, please contact the manufacturer (EyoungTech) for repair/replacement.

Key Takeways

Issue Types | Symptom | Disgnosis | Solution |

Obstruction | "65535m" readings | Check lens & environment | Clean lens, remove obstacles |

Misalignment | Angle-dependent errors | Test at different angles | Recalibrate optical axis |

Laser failure | No laser spot, unstable current | IR card test, self-check function | Factory repair |

Conclusion

Laser rangefinders are a marvel of modern engineering, but their accuracy masks a fragile reliance on numerous variables. Understanding why these laser ranging devices return invalid distance values requires an understanding of the subtle relationship between hardware integrity, environmental stability, and firmware sophistication. With this knowledge, engineers and technicians can better diagnose problems, fine-tune deployments, and push the limits of precision sensing in the field.

Insights into Laser Rangefinders & Gimbal Cameras

Other Optoelectronic Devices You May Like

About the Author & Team, Eyoung Tech

Hey, this is EyoungTech, a China-based professional team dedicated to advancing optoelectronic innovation.

With a steadfast focus on optoelectronic products represented by laser rangefinders and UAV payload pods, we deliver comprehensive, end-to-end solutions to leading international partners in the UAV & drone and defence sector. Backed by years of collective expertise, our stable, highly skilled workforce ensures rock-solid technical performance and unwavering support at every stage — from initial design through deployment and beyond. At Eyoung Technology, your mission success is our top priority.

The purpose of this article is to share with insight related to cutting-edge technlogy and product applications in defence, surveying of drone industry.

Eyoung Laser Ranging Devices and Gimbal Cameras

Related Eyoung and Photoelectric Products Article for Reference

Gimbal Cameras

Gimbal Cameras